+86 25 6959 0453

+86 25 6959 0453

sales@chamlion.com

sales@chamlion.com

2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Geopolitical conflicts, wars, epidemics… the year 2022 will have a profound impact on all aspects of life. The “capital winter” has become a tacit consensus among all, and many companies are retreating and “surviving the winter” with difficulty.

But also in 2022, a company in Nanjing Software Valley Entrepreneurship and Innovation City bucked the trend and rose across the board

This miracle-making enterprise is Nanjing Chamlion Laser Technology Co., Ltd. (later called “Chamlion Technology”).

Since its establishment in 2017, Chamlion Technology has started from an inconspicuous office in Nanjing Software Valley Entrepreneurship and Innovation City. It has upgraded its strategy from “Chamlion Laser” to “Chamlion Technology”, and has evolved from a dental 3D printing equipment manufacturing enterprise. It is a digital service platform for the whole process of dentistry that is now running around the world. How did Chamlion Technology grow rapidly in just 5 years? What are the considerations behind the name change? How did it soar against the trend? How will the company plan in the future? In response to these questions, Arterial.com interviewed Wang Zhitao, CEO of Chamlion Technology, trying to get a glimpse of the answer.

Wang Zhitao, CEO of Chamlion

Wang Zhitao, CEO of Chamlion

From “Chamlion Laser” to “Chamlion”

Promote the digital upgrade of the whole process of dentistry

Chamlion Technology is a national high-tech enterprise incubated and established by the Additive Manufacturing Institute of Nanjing University of Aeronautics and Astronautics. It focuses on the digitalization of the entire process of stomatology and provides one-stop dental 3D printing digital solutions.

The company has successively developed dental-specific 3D printers, denture intelligent design software, and post-processing automation equipment with independent intellectual property rights, realizing the digitalization of the entire dental industry chain. Based on the “Internet” + 3D printing, the company has built a large-scale distributed denture manufacturing cloud factory on a global scale, opened up the data-design-manufacturing process of denture processing, and built a digital service platform for the whole process of dentistry.

Chamlion

Chamlion

From the beginning of its establishment to 2021, Chamlion laser has worked hard to research technology and has successfully developed a pure titanium metal powder coating 3D printer for dentistry and a cobalt-chromium metal powder coating 3D printer for dental use, providing a one-stop metal 3D printing solution. Improve the processing efficiency of the denture factories.

some hardware equipment products of Chamlion

some hardware equipment products of Chamlion

According to the data provided by Chamlion, using Chamlion Technology’s proprietary 3D printing process, the qualified rate of printed products can reach 99.2%. With super high-cost performance, Chamlion Technology’s dental 3D printing equipment not only leads the industry in terms of shipments, but also suppresses imported manufacturers internationally, and is exported to the United States, Canada, Italy, South Korea, the Philippines, and other countries, becoming a Chinese dental 3D printing equipment.

In May 2021, Chamlion has fully transformed into a cloud factory model, and its strategic layout has changed from a pure hardware supplier to a dental full-process digital service platform. Talking about the thinking behind it, Wang Zhitao said that in recent years, the development of domestic 3D printing hardware has become increasingly mature, but the development of software has been relatively weak. The CAD/CAM software dedicated to dental 3D printing is almost monopolized by foreign countries.

Therefore, Chamlion has devoted itself to researching and developing a variety of dental 3D printing software, including 3D printing equipment control software, data processing software, denture intelligent design software, etc., to realize the localization of dental 3D printing software. Among them, denture intelligent design software is based on artificial intelligence and big data and adopts graphic recognition algorithms, which greatly improves design efficiency.

With the rapid development in the field of dentistry, Chamlion found that “the digital level of upstream oral products largely determines the upper limit of downstream clinical service levels. Upstream digitalization can provide consumers with customized precision medical solutions. and scientific modeling solutions to improve the efficiency of doctors’ diagnosis and treatment and the user’s treatment experience and effect.”

Therefore, in May 2021, the company fully transformed into a cloud factory model and officially sounded the charge of digital services for the whole process of dentistry.

Signed contracts with 27 countries to deploy 260 dental cloud factories

Provide a digital platform for the whole process of dentistry

In addition to being on the fast-growing track of digital dentistry, the reason why Chamlion can achieve rapid development lies in its high-quality team, products, and solutions.

The first is the team aspect. Wang Zhitao said that the advantages of Chamlion are reflected in four aspects. The first is to have material research and development capabilities, directly master the underlying capabilities of upstream raw material research and development and manufacturing technology; the second is to have the ability to develop localized software and commercial applications, including the global cloud order platform system, intelligent production scheduling system and Dental industry CAD design software, etc.; the third is to have the R&D and manufacturing capabilities of dental printers; the fourth is to have the ability to coordinate global operations.

At present, many domestic dental companies only have one or two of these capabilities, and it is difficult to take care of all four. Especially from the perspective of global operations, how to maintain the vitality and efficiency of the organization has become the biggest problem for many enterprises to sail globalization. In response to this pain point, Chamlion has attracted many operation and management talents from large global enterprises. At present, the entire operation team is composed of local Chinese talents. The company exports materials, technology, and automated production lines, while core data and software are left in the Chinese data center for processing. Local customers provide ordinary workers. Chamlion uses integrated technology to help customers complete intelligent manufacturing of most processes.

In terms of product structure, Chamlion does not focus on the digital transformation and upgrading of individual elements but pays more attention to the digitalization of the whole process. Through the R&D and innovation of materials and software, Chamlion drives the hardware, and finally realizes the digital manufacturing of the entire industry chain and empowers denture processing.

Take the Chamlion Cloud Platform as an example. The Chamlion cloud platform transforms traditional labor-intensive denture processing into a systematic, streamlined, and standardized work through AI.

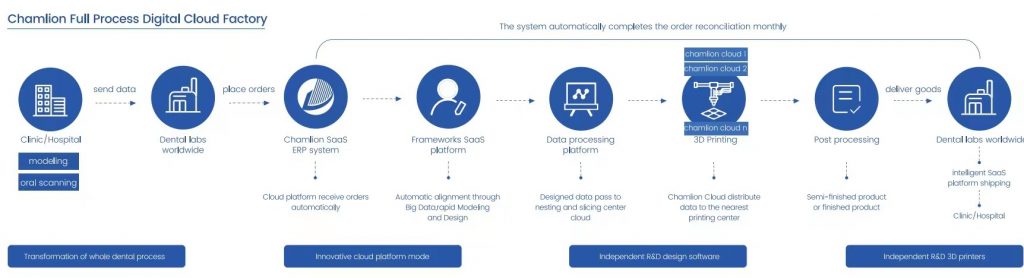

Specifically, the Chamlion cloud platform acts as the central brain, connecting various elements such as hardware, software, and design teams to form a distributed manufacturing cloud factory. Users send task requirements through the cloud platform, and the digital design team conducts industrial CAD design and data processing online. The intelligent production scheduling system of the cloud platform assigns printing tasks to the optimal cloud factory to complete the production of semi-finished or finished products and finally sends the products to the user. Taking the printing of semi-finished products as an example, it only takes 24 hours from the receipt of the demand on the cloud platform to the delivery of the product, realizing the digitization and intelligence of the whole process of denture processing.

Chamlion full-process digital cloud factory

Chamlion full-process digital cloud factory

Wang Zhitao told Arterial.com, “Any denture factory in the world can upload data to Chamlion Cloud to complete the action of placing an order. Subsequent CAD design-data processing-printing-digital manufacturing, etc. are completed automatically. Moreover, all clouds in the world the factories are all self-operated by Chamlion, and we obtain income by providing digital manufacturing capabilities to laboratories around the world and charging product service fees according to orders.”

The innovation of the Chamlion cloud platform is not only that it can network all metal printers into a denture printing cloud factory, which can greatly reduce the end customer’s expenses while ensuring product quality and production efficiency and achieve cost reduction and efficiency increase. It brings more business growth and outlines more possibilities for 3D printing to change from simply selling equipment to cloud services.

Such innovations are also reflected in materials. Chamlion is developing titanium-zirconia alloy materials for 3D printing implants. This material not only has excellent mechanical properties and biological properties but also has no magnetic properties and basically has no effect on nuclear magnetic resonance. It is an ideal dental material.

Attack the global market

Set off a digital storm in the whole process of dentistry

Up to now, Chamlion has entered 27 countries including the United States, Canada, Italy, Turkey, Vietnam, and Dubai, established more than 260 cloud factories, produced 80,000 dental crowns and 8,000 movable brackets a day, and served 30 million global users.

With the restoration of the global market value after the epidemic, the promotion of the digital dental industry, and the acceleration of global aging, the dental industry is bound to usher in a new round of outbreaks.

“In the future, 70% of Chamlion’s business will be overseas.” Wang Zhitao told Artery.com that in 2023, the company will deepen its overseas multi-point layout, promote the construction of localized services, gradually promote the international strategic layout, and build with global denture technician enterprises. The ecological partner system jointly promotes industry integration and digital development.

At the same time, Chamlion will continue to make efforts on the raw material side, the software side, and the equipment side, deepen innovation, use innovation as a shield to go through different industry cycles, and provide a “Chinese solution” for the digitalization of the world’s dentistry.