+86 25 6959 0453

+86 25 6959 0453

sales@chamlion.com

sales@chamlion.com

2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

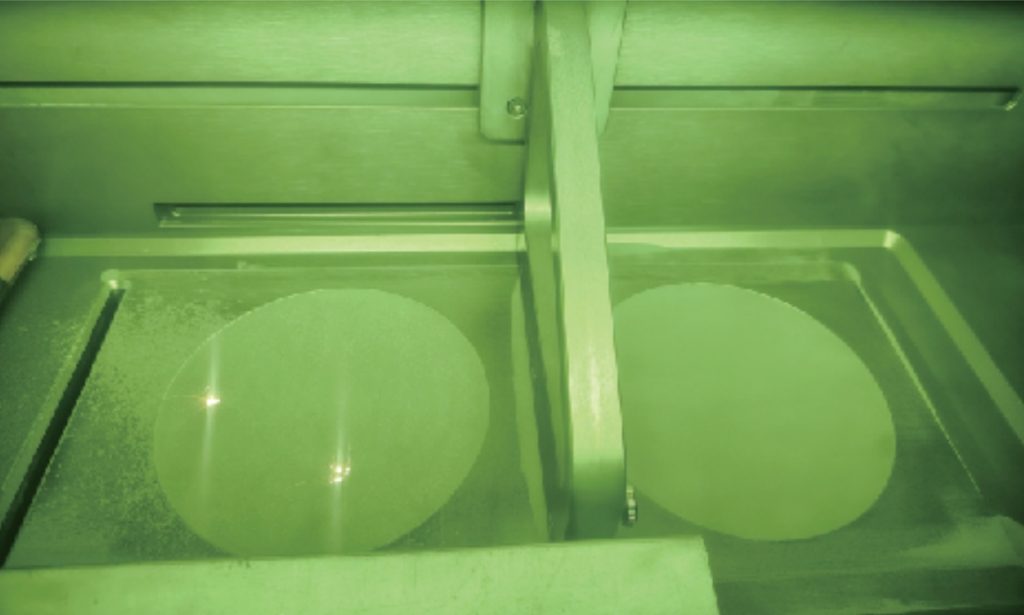

During the initial equipment debugging process of 3D printing, the powder spreading step is crucial. Whether the powder is spread properly directly affects the success of tooth printing. Next, I will elaborate on the precautions during the powder spreading process.

Firstly, the substrate needs to be polished clean and smooth. In usual operations, whether it’s cobalt-chromium substrates or titanium substrates, they are both recycled. However, during the annealing process, a thick layer of oxide will always form on the surface of the substrate, and the surface is prone to warping and deformation when heated. Therefore, before each printing, the surface oxide layer of the substrate needs to be polished clean and smooth to ensure no dirt or oil stains. This is the basis for leveling the substrate and directly affects the even and smooth spreading of the powder.

Secondly, the scraper blade needs to be replaced and adjusted in time before each printing. During the 3D printing process, the scraper blade frame drives the scraper blade to move back and forth in a continuous cycle, evenly spreading the powder on the substrate, layer by layer, forming the shape of the teeth. Like the substrate, the scraper blade wears out with each printing. If abnormalities are not detected and replaced in time, it will cause streaks or wave patterns during powder spreading, severely affecting the printing effect, and even leading to printing failure.

At the same time, when adjusting or replacing the scraper blade, attention should be paid to the skillful handling of the hands. When placing the scraper blade, it should be fully fitted into the groove, and when tightening the screws, the three screws should be tightened evenly in a cycle, instead of focusing on one screw to tighten it completely. Similarly, when fixing the substrate, the same principle applies. Avoid using brute force to tighten the screws, causing unnecessary mistakes and troubles. Also, before each printing, attention should be paid to observing the scraper blade frame module to ensure smooth operation without abnormal noise.

Furthermore, when filling the powder into the chamber material cylinder, use a scraper to compact and flatten the powder, and check whether the software part height and feeding height are normal.

Finally, it is necessary to check whether the equipment cylinder is running normally. During equipment debugging, click on the forming cylinder and material cylinder to move up and down and observe whether there are any alarms. Then, using a brass micrometer, select three points respectively, and the difference in values should not exceed 10 divisions.

In summary, leveling the substrate and evenly spreading the powder are crucial in the 3D printing process. They should be given constant attention during routine equipment inspection and maintenance.

About Chamlion

Digital transformation and upgrading of your dental lab has never been easier!

We assist you on the entire journey with customer-specific integrated solutions, allowing you to enjoy onsite 3D printing without having to purchase equipment.

Chamlion offers not individual products, but complete solutions from a single source: equipment, materials, software, process parameters, global support as well as a flexible range of services such as designing and post-processing.