+86 25 6959 0453

+86 25 6959 0453

sales@chamlion.com

sales@chamlion.com

2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

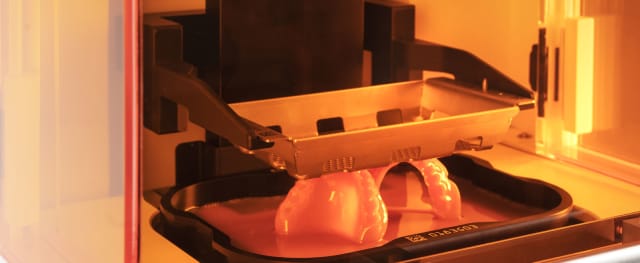

As more practices move to digital dentistry, additive manufacturing is playing a key role in improving patient care.

3D printing is taking on an increasingly prominent role in the dental industry. At LMT Lab Day 2022 held in late February in Chicago, additive manufacturing companies unveiled several new technologies designed to help practitioners and patients alike. Let’s take a closer look at some of them.

Formlabs and Medit Partner to Facilitate Chairside 3D Printing

One of the hurdles in getting dental practices to adopt digital processes is making the technologies easier and more accessible. 3D printing company Formlabs has partnered with Medit, a global provider of dental 3D scanners, to enhance chairside 3D printing.

The Medit Link dental platform—an integrated system that enables dental clinics and labs to communicate and collaborate—can now integrate with Formlabs’ PreForm app, a software integration tool that helps prepare CAD designs. Dentists can now 3D print directly from Medit Link through the app, increasing convenience and speed in creating dental products for a patient while they’re still in the chair. Dental professionals can use Medit intraoral scanners to scan patients’ teeth. With the PreForm app, they can easily convert those scans into 3D models and appliances and print them with a Formlabs Form 3B+ printer.

“Together, we’ve created a complete chairside workflow that addresses these barriers to make the technology more accessible, with the ultimate goal of unlocking the benefits of dental 3D printing for both providers and patients,” said David Lakatos, chief product officer at Formlabs.

The partners plan to pair Formlabs products such as Formlabs Dental with Medit i500 and i700 intraoral scanners to bring reliable and easily integrated 3D printing to the dental office—without the need for extensive training or other costs.

“The integration of Formlabs and Medit combines best-in-class 3D printers with the industry’s fastest intraoral scanner. This will inevitably bring about great synergy, resulting in easier access to a complete chairside solution,” said Inhaeng Cho, Medit’s chief strategy officer.

3D Systems and Saremco Enter Partnership to Accelerate Digital Dentistry

Another partnership announced at Lab Day 2022 was between 3D Systems and Saremco Dental AG. 3D Systems already operates in the dental field through its NextDent subsidiary, which provides 3D products and services to the sector. Saremco Dental AG’s expertise is in the development and production of light-curing resins for the industry. The companies are partnering to use additive manufacturing technologies to produce permanent crowns that are specific to a patient, with increased accuracy and speed while lowering total costs.

Saremco will provide its CROWNTEC composite resin, recently approved by the U.S. Food and Drug Administration, for use in 3D Systems’ NextDent 5100 dental 3D printer. Saremco describes CROWNTEC as a new generation of composite resin that can be used to 3D print biocompatible products, including crowns, inlays, veneers and artificial teeth for dentures. With the NextDent printer, the material can be leveraged by labs and clinics to produce dental restorations that are 30 percent stronger than previous generations of crown and bridge materials.

“Our goal is to enable dental professionals to become more efficient and by doing so, ultimately improve patient outcomes,” said Stef Vanneste, vice president and general manager, dental, 3D Systems. “As we innovate to meet our customers’ application needs, this strategic partnership plays a key role in helping to enhance our materials portfolio. [Saremco’s] CROWNTEC material is a strong complement to our NextDent material portfolio, and is yet another step in helping dental professionals improve patient outcomes.”

CROWNTEC joins 3D Systems’ roster of 30 NextDent resins, including the Class IIa biocompatible C&B Micro Filled Hybrid, which is used for creating provisional crowns, bridges and artificial teeth. CROWNTEC gives labs and clinics an aesthetic option for those products—and it can also be used to make permanent crowns.

Xact Metal Introduces Metal Printing Innovations

Xact Metal, a metal 3D printing company, announced at Lab Day 2022 that it is expanding its 3D-printed metal dental applications with its recently introduced XM200G single- and dual-laser metal 3D printers.

The printers feature a large 150 mm by 150 mm build area, rapid and precise galvanometer mirrors, F-Theta lens optics and dental-specific parameters at 50 µm laser spot size and 20 µm build layers. This makes the printers optimal for creating products such as crowns, bridges and removable partial dentures.

Xact Metal is offering the printers as a package with technologies from Materialise and BEGO Medical. The printers will come equipped with Materialise’s Pre-Print Dental Module software. This will enable a workflow specialized to dentistry that will include classification, error repair, print positioning, optimized support structures and part nesting during the design and optimization of dental components. The module is fully integrated into the Materialise Magics intuitive software for Xact Metal to facilitate the 3D printing process. As a result, dental practitioners and labs will be able to edit and repair files, program the print bed and formulate instructions for the printer.

In addition, Xact Metal’s printers will be able to use two certified BEGO Medical dental powders. Mediloy S-Co is a cobalt-based alloy for printing crowns, bridges, denture frameworks, implant prostheses and other orthodontic procedures, while WIRONIUM RP is a nonprecious metal biocompatible and corrosion-resistant alloy for specific use in creating removable partial denture frameworks.

“At Xact Metal, we’re taking the essential specs of metal 3D printing and combining them with breakthrough technology to establish a new level of price and performance for the dental industry,” said Juan Mario Gomez, CEO of Xact Metal. “We have developed a high-performing and complete solution for dental labs…. The package [including Materialise and BEGO Medical products] will make it simple for dental labs to begin printing quickly and for a low cost.”

How digital dentistry works and its future in the dental field.

3D printing is having a significant impact on the way dental practices conduct their business and care for patients. In fact, 63 percent of the respondents to LMT’s 2021 3D Printing Survey say they have incorporated 3D printing into their practices, whether in-house or through outsourcing.

The technology can help practices and labs reduce costs, work more efficiently and create better quality products in less time than conventional methods. From dentures to crowns to nightguards to sports mouthguards, the technology is enabling dental offices to improve the care they provide in their clinics.

Mass customization allows dental products to be made with improved accuracy and speed while retaining the ability to customize each item to meet the unique needs of the patient. Desktop printers are allowing dental practices of any size to integrate on-demand manufacturing into their businesses on-site. And 3D-printed products created at a high degree of accuracy and speed helps providers give better care. For example, the conventional process for creating a denture can often take weeks and involve a fair amount of back-and-forth between the dental office and the dental lab—while a desktop 3D printer could create the product in the same day.

If the partnerships and products showcased at Lab Day 2022 are any indication, the shift to digital dentistry is gaining momentum and the field is constantly innovating—which could make your next visit to the dentist a much more comfortable experience.

Read more about the technologies used in digital dentistry at Formlabs Announces the Form 3+ 3D Printer.